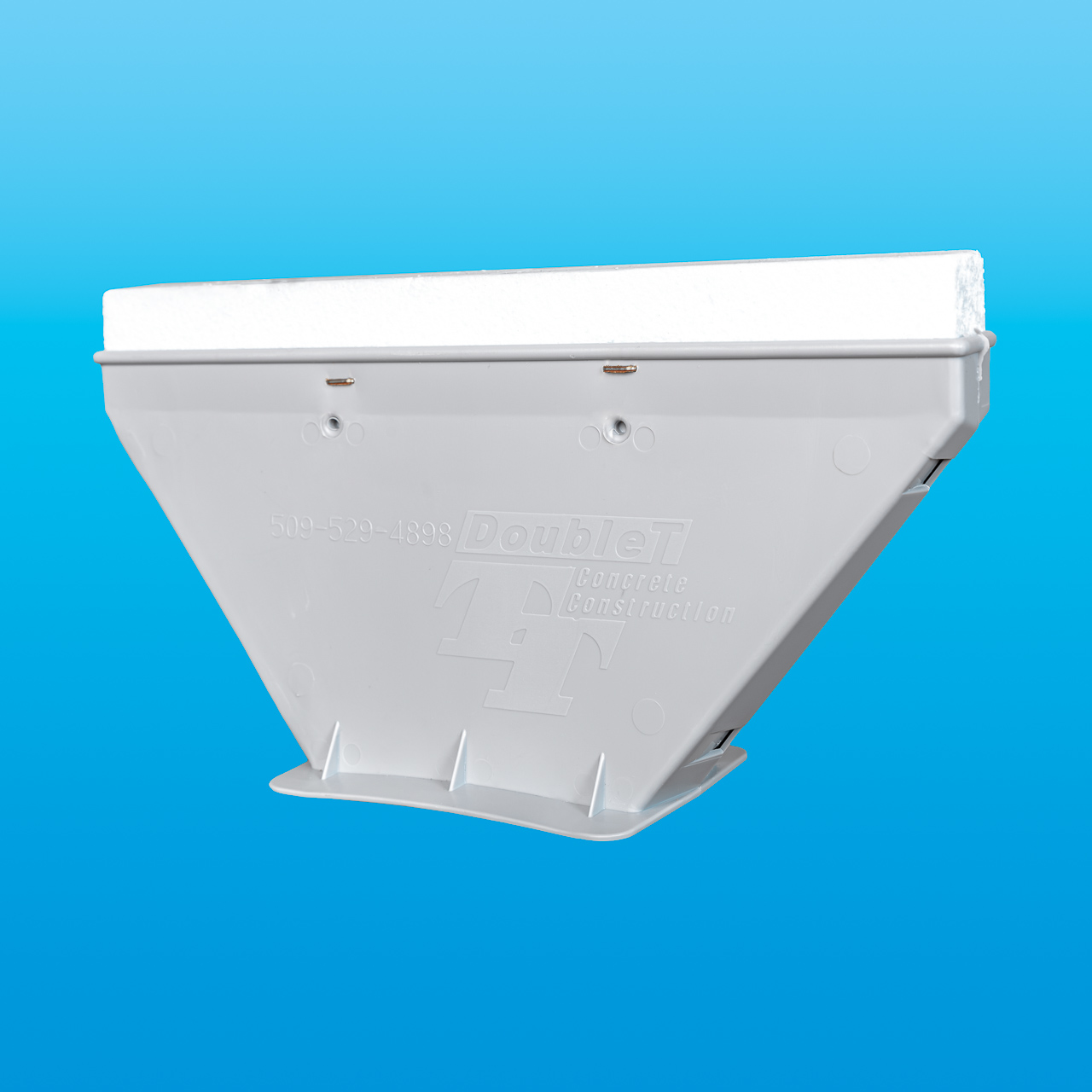

Plastic Injection Molded High Impact Polystyrene Agricultural Storage Floor Vent

The project highlighted here is the result of a joint effort between Gordy Plastics and an agriculture industry customer. Through a collaborative effort this vent was developed, patented, and implemented in agricultural storage facilities across Oregon and Washington State. The vent was designed to prevent the rotting of produce (onions and potatoes) in bulk storage by increasing air flow in the storage area. This delivered a product loss decrease from 14% to 7%, providing an ROI of one year.

The vent is composed of a high impact polystyrene (HIPS), which is injection molded with a 5 oz. shot into a two cavity mold at 430°F to 450°F; this allows tolerances of ± 0.005″ to be achieved. The finished product is light gray in color, with a smooth finish and dimensions of 11″ in length, 3″ in width, 5″ in height, and 0.100” thick. After trimming it weighs 4.5 oz. Once the molding of the two-part vent is assembled, foam is inserted and the parts are stapled to seal. We currently manufacture 50,000 of these vents per month, with lead times of 2 weeks.

For more information on this project, or the processes used to manufacture it, see the table below or contact us directly.